In the throes of the Gulf oil disaster, Americans have suspended off-shore oil exploration and drilling. Fearful that the BP blow-out will destroy the unique culture and commerce that have distinguished America's Gulf Coast, they do not want to risk it. When the panic subsides, though, and when the skimmers finish recovering all the oil from the warm Gulf stream waters, those same Americans will have to come to grips with the fact that they depend on the oil industry for sustaining exactly the culture and commerce they cherish. Offshore oil drilling will resume. In fact, the oil industry will stand as one of the cornerstone's in the Gulf Coast's renaissance. And many oil experts predict that offshore drilling will resume off the coast of California, too. America will repress its passion for safety and environmental protection in order to quench its thirst for oil and gasoline.

Patience, precision, and safety will prevail.

The Obama administration already has reorganized the agencies responsible for regulating offshore drilling, effectively eliminating corruption in the system. The college interns no longer can throw together safety plans using dad college professors and imaginary experts as their sources and contact people. Safety engineers will have to conduct genuine tests of fail-safe equipment under the watchful eyes of people who actually know how the equipment ought to function. And evacuation plans will have to provide real escape routes for terrified workers on exploding rigs. If the oil producers have learned nothing from the BP debacle, however, they surely have learned that, in the long run, it costs far less to do the work correctly than it costs to attempt corrections after a disaster.

The Deepwater Horizon experience has provided ample illustration of what happens when engineers and technicians settle for quick and dirty solutions to complex problems. The old adage "can't see it from my house" may get the pipe into the ground and some of the oil onto the boat, but the problems will become visible from everybody's house when even one of the quick-fixes fails. In the most crass actuarial terms, the Deepwater Horizon experience also has taught that a functional blow-out preventer costs considerably less than eleven human lives.

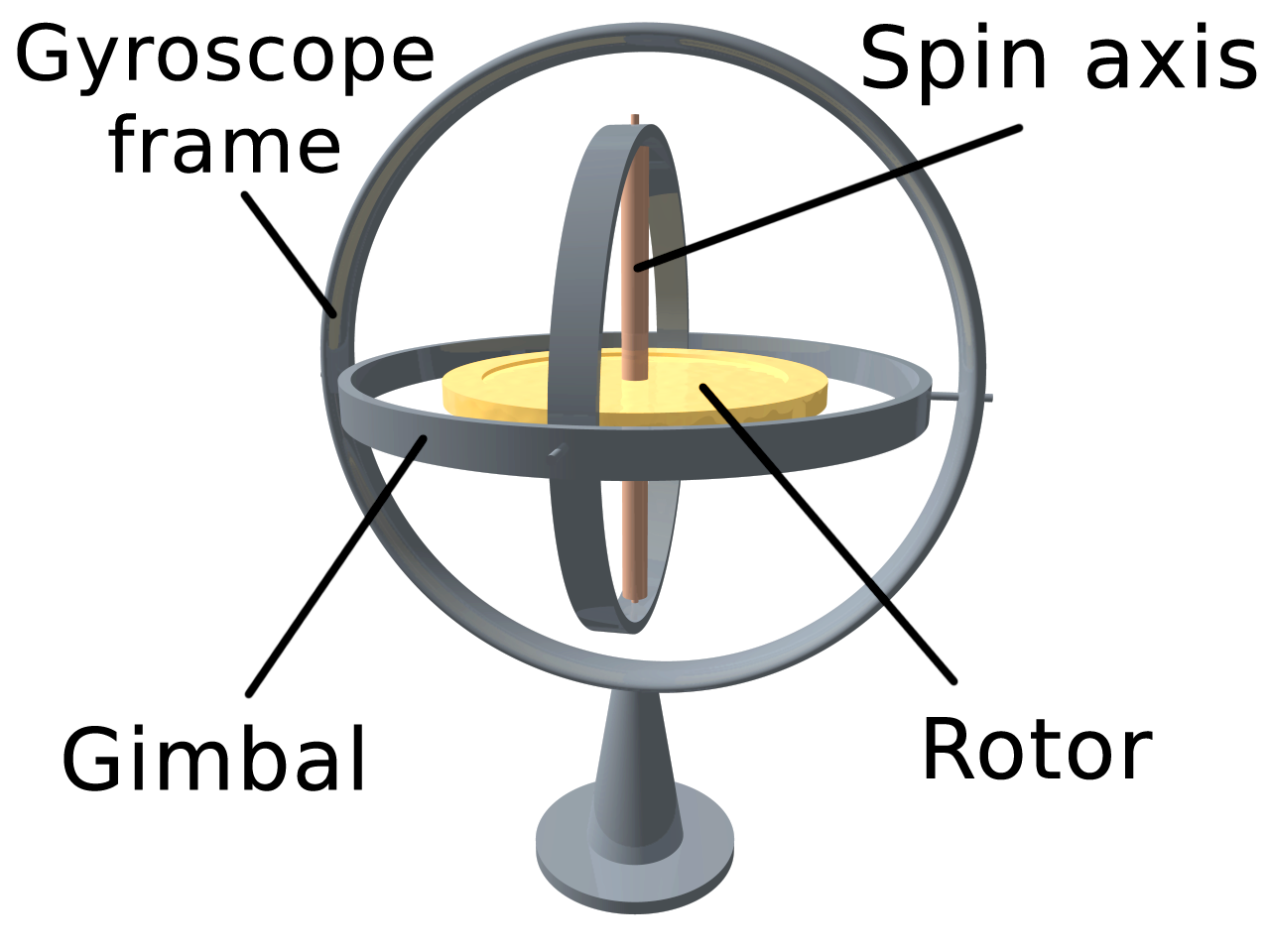

Every bit of sight-line, gyroscopic, sonar, radar, and robotic technology must be mobilized in the development of each new well, not only to assure the well's safety and integrity but also to ensure its long-term productivity. The industry must remember that, for every four barrels technicians have extracted from every well they ever have dug, they have left six barrels in the ground,. The industry has not mastered the technology to get full production from every well it sinks. In the twenty-first century, the oil industry must set its sights on 100% production from every well. Therefore, it must set its sights on structurally sound drilling intended to withstand pressures far greater than those Mother Nature exerts.

The latest gyro technology shows great promise.

Given that offshore drilling will resume under tighter-than-ever supervision and constraint, the industry must continue improving its drilling tools and guidance technology. Some of the industry's equipment has neither advanced nor evolved since the end of the nineteenth century, yet the drill sites become more dangerous and vulnerable with each new attempt.

The newest gyro technologies and gyroscopic devices show the greatest promise for assuring precision drilling, and industry engineers now clearly understand how borehole precision ultimately translates to system integrity. Gyro-guidance eliminates the need for wire-line gyros, and it especially increases the precision with which engineers can drill at unusual trajectories or oblique angles. The newest gyro technologies also remain unaffected by magnetic interference so that they can run closer to the bit without complicated splices and extra hardware.

Article Source: http://EzineArticles.com/4862722

没有评论:

发表评论